Unlocking New Possibilities with High-Performance Stainless Steels

Interview with Lucas Kling, CEO Services & Solutions France – Head of Finishing France

We are excited to discuss the role of high-performance stainless steels in energy transition technologies and beyond with Lucas Kling.

Lucas shares insights into how these advanced materials are shaping the future of multiple industries, from energy to mobility.

- Q: Many might assume that metal production is a traditional industry with little room for innovation. How does Aperam approach innovation, particularly in high-performance materials?

Lucas Kling: That’s a great question. While stainless steel production is indeed a long-standing industry, significant innovations are constantly being driven by new markets, applications, and technological constraints. My role at Aperam involves identifying these emerging challenges and opportunities. Once we understand what the market needs, we look inward to evaluate our capabilities and push the boundaries of material innovation. Through collaboration with various teams, we develop solutions that meet market demands, and this is especially important in sectors undergoing rapid change, such as energy transition technologies.

- Q: I thought that all stainless steel was naturally corrosion-resistant. From what you’ve said, it seems there are different levels of performance. Can you explain more about high-performance grades?

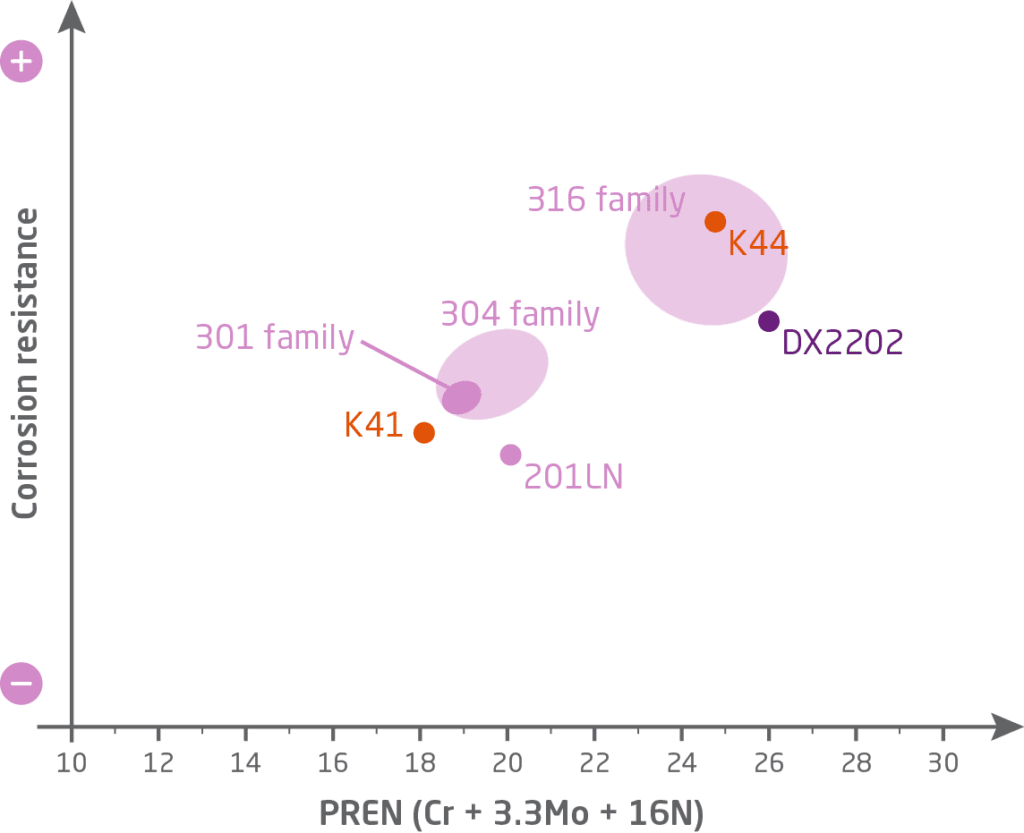

Lucas Kling: Absolutely. Stainless steel is inherently corrosion-resistant due to its chromium content, but the level of corrosion resistance can vary depending on the composition of the material. High-performance grades, such as duplex and super austenitic stainless steels, are specifically engineered to offer enhanced properties for demanding environments. It’s similar to cooking—you can add different ingredients to enhance the flavor of a dish. In the same way, we adjust the chemical composition of our stainless steels to suit the specific performance requirements of each application.

- Q: Speaking of applications, where are these high-performance materials most commonly used?

Lucas Kling: These materials are critical across a variety of industries, from food and beverage to energy and mobility. For example, in the biofuel industry, storage tanks for feedstocks require materials with extremely high corrosion resistance. Meanwhile, in the energy sector, electrolyzers, which are used to generate hydrogen, operate at high temperatures and require materials that can withstand both heat and corrosion. Our expertise allows us to match the right material to the right application, ensuring long-term performance and reliability in these challenging environments.

- Q: How does Aperam differentiate itself from competitors in the high-performance materials market?

Lucas Kling: Aperam stands out through continuous investment in cutting-edge technologies and R&D. Our facilities are equipped with the latest production capabilities, and we place a strong emphasis on innovation. For example, Aperam is the only European producer of duplex stainless steel coils up to 13 millimeters thick. This is a significant advantage because it allows us to offer a product called Coil Mill Plate, which has a more homogeneous surface and better thickness control than traditional plate mill products. This results in faster, more efficient manufacturing for our customers. We also produce extremely thin duplex grades, as thin as 0.5 millimeters, which are used in critical applications like the nuclear industry.

- Q: What role do stainless steels and special alloys play in the energy transition?

Lucas Kling: Stainless steels and special alloys are essential enablers for the energy transition. As we move toward cleaner energy sources, new technologies bring with them new challenges. Stainless steel is highly adaptable, which is crucial for sectors like geothermal energy, wind turbines, solar power, and biofuels. For example, in the biofuel industry, processing involves highly corrosive environments that require specialized materials like duplex grades and super austenitic steels. For high-heat applications, grades like 310S and 309N are critical. At Aperam, we are committed to developing the best materials to support these new energy technologies.

- Q: It seems like collaboration is key in developing these new materials. Can you give us some examples of partnerships Aperam has formed in this field?

Lucas Kling: Absolutely. A concrete example comes from our work in the biofuel sector. We collaborated with a partner (whose name I can’t disclose for confidentiality reasons) to optimize the material selection for large storage tanks used to store biofuel feedstocks. These tanks can be up to 30 meters high and 8 meters in diameter, requiring massive amounts of material. By substituting the initial material selection with a more high-performance grade, we were able to reduce the thickness of the steel without sacrificing strength or durability. This resulted in lower material usage, which not only reduced the cost for the customer but also minimized the environmental impact—demonstrating that sustainability and cost efficiency can go hand-in-hand.

- Q: What’s next for Aperam?

Lucas Kling: Our next challenge is to continue delivering high-quality solutions while expanding into new market segments. We’ve launched a special internal program called the Sponsorship Program, which focuses on driving innovation in areas like energy transition and beyond. We are continuously working to develop new products and improve existing ones, ensuring that Aperam remains at the forefront of material innovation.

- Q: Thank you, Lucas, for sharing these valuable insights. It’s clear that high-performance stainless steels play a crucial role in driving innovation and supporting energy transition technologies.

Lucas Kling: It’s been a pleasure to discuss how Aperam is contributing to the development of these exciting new materials. The role of stainless steel in extending product lifecycles and enabling new applications in environmental and energy transition technologies is truly exciting. I look forward to continuing these conversations as we explore even more opportunities.

Want to learn more? Contact Lucas Kling

-0,84%

-0,84%