Exploring the Role of Stainless Steel in Electric Mobility

Interview with Gwénaëlle Le Meur and Charles David

Industries are facing new challenges, particularly with the rise of Electric Mobility. Today, we delve into these challenges with Gwénaëlle Le Meur, Director of Market Innovation & Development, and Charles David, Head of Consumer Goods & Construction at Aperam. They discuss the role of Aperam, in revolutionizing the materials used in electric vehicles (EVs) and beyond.

- Q: Gwénaëlle, can you tell us about your role and background at Aperam?

Gwénaëlle Le Meur: I am the Director of Market Innovation & Development at Aperam, a position that was created to establish Aperam as a preferred supplier for new mobility applications. Before joining Aperam, I worked in the automotive industry, leading strategic innovation projects. My current role allows me to continue exploring the future of mobility, focusing on innovative materials for electric vehicles and other forms of transport.

- Q: Coming from the automotive sector, how does the stainless steel industry compare in terms of innovation?

Gwénaëlle Le Meur: Before joining Aperam, I also thought that the steel industry was perhaps less focused on technological innovation. But after working here for several years, I’ve seen firsthand that innovation is central to what we do. Aperam, for example, has pioneered a process that uses plants to extract nickel from the soil for stainless steel production. We are constantly improving our processes and products, and we stay at the forefront of technical advances, particularly in the mobility sector.

- Q: Can you provide some examples of innovations Aperam is working on in Electric Mobility?

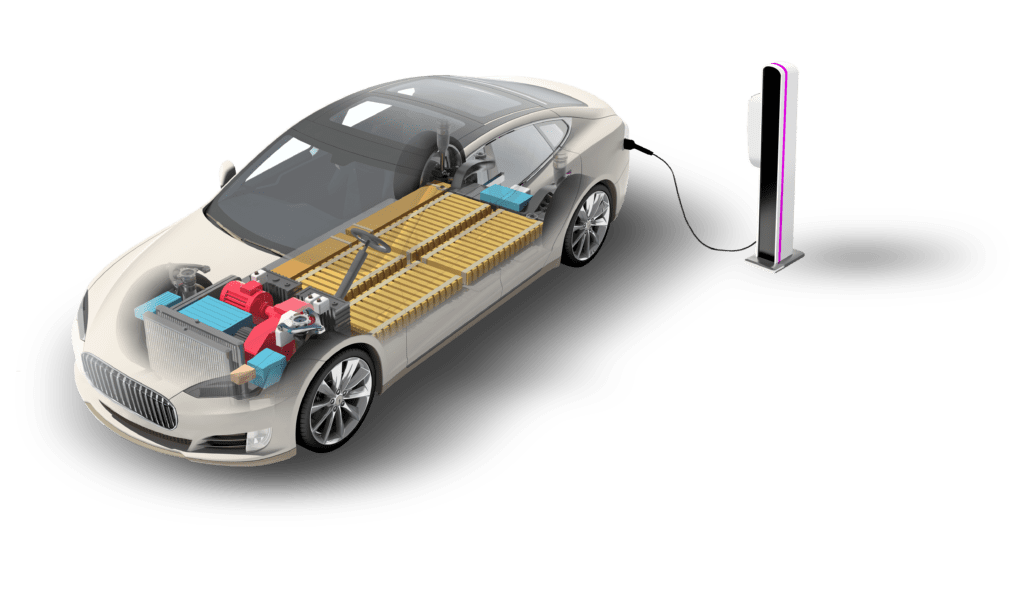

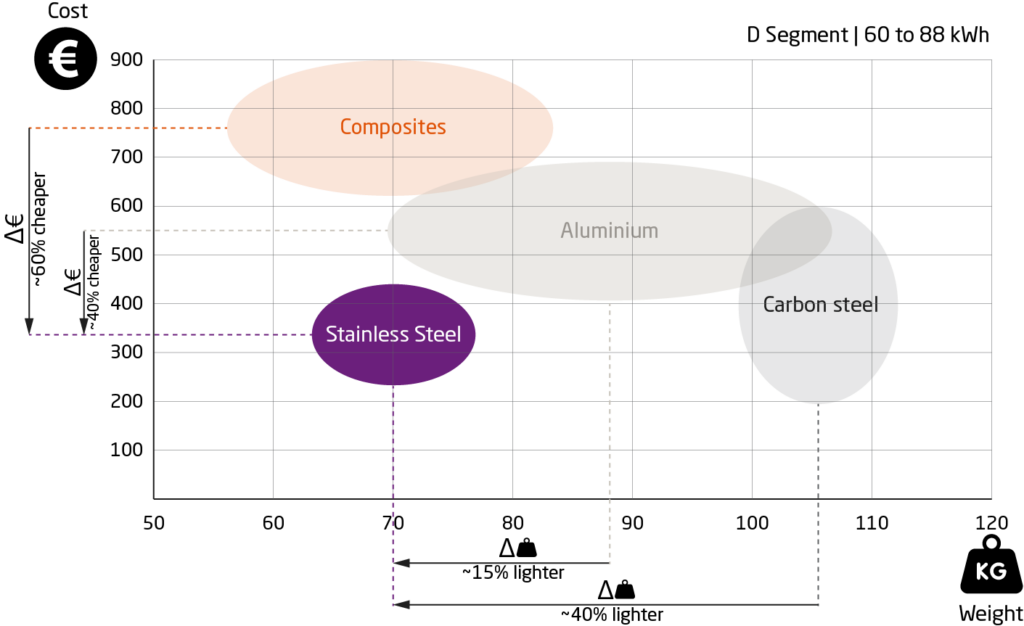

Gwénaëlle Le Meur: One of our most exciting developments is in the realm of battery technology for electric vehicles. We’ve developed two innovative concepts for EV battery housings that are not only more cost-effective but also lighter, safer, and offer higher energy density compared to traditional carbon steel and aluminum options. We are also working on emerging technologies like solid-state batteries, which are expected to revolutionize the EV industry.

- Q: So, your focus is not just on electrification but also on other areas of mobility?

Gwénaëlle Le Meur: That’s right. While electrification is a key area for us, we are also exploring hydrogen mobility and the decarbonization of transport. Our goal is to address the pain points of our customers, whether through established technologies or by embracing innovations. It’s about driving the mobility revolution with the right materials and solutions.

- Q: How does Aperam manage to combine innovation with customer needs?

Gwénaëlle Le Meur: I’m fortunate to lead a team of specialists who bring expertise from diverse fields—automotive, research and development, and metallurgy. Charles, who is with us today, is a perfect example of this interdisciplinary approach.

- Q: Charles, can you tell us about your role and background at Aperam?

Charles David: Certainly. My focus is on the electrification of mobility. I work on translating complex technical topics into business solutions that fit our customers’ needs. I have a PhD in metallurgy and corrosion, and I’ve worked in Aperam’s R&D division, as well as in our sales team. Since joining the new business team last year, I’ve been working on projects related to both stainless steel and alloys, particularly in the electrification of vehicles.

- Q: It’s interesting that you mention alloys. Can you explain Aperam’s role in this field?

Charles David: Absolutely. While Aperam is widely known for its stainless steel, we also produce high-value alloys, especially nickel alloys. These materials play a critical role in power electronics and electric motors. For example, we manufacture iron-cobalt alloys, known as AFK grades, which are emerging as an alternative to traditional iron-silicon alloys used in electric motors. Our grades increase power density by 20%, which is a significant advantage.

- Q: Can you elaborate on how these materials contribute to the electrification of mobility?

Charles David: There are three key pillars of car electrification: the battery, the electric motor, and power electronics. Aperam is actively involved in all three. For electric motors, our iron-cobalt alloys enhance power density. In terms of batteries, we’re developing stainless steel solutions for battery housings, which are safer, lighter, and more cost-effective than traditional materials. And for power electronics, we produce magnetic alloys and components that are essential for systems like inverters and converters to function efficiently.

- Q: It sounds like a challenging but rewarding role. Gwénaëlle, what are the biggest challenges you face in your work?

Gwénaëlle Le Meur: One of the biggest challenges is overcoming preconceived notions about the materials we use. Many in the industry still believe that stainless steel is too expensive or too heavy compared to carbon steel or aluminum. But our research and developments show otherwise. We aim to prove that stainless steel can deliver the performance, safety, and cost-effectiveness needed for the future of mobility, particularly in electrification, hydrogen mobility, and decarbonization.

- Q: Thank you both for your insights. It’s clear that Aperam is playing a pivotal role in the mobility revolution.

Gwénaëlle Le Meur: Thank you for having us. It’s an exciting time to be in this industry, and we’re proud of the work we’re doing at Aperam to drive innovation in mobility.

Charles David: Yes, we look forward to continuing our efforts to develop materials that meet the needs of tomorrow’s transportation systems.

Want to learn more?

0,67%

0,67%