What We Mean By Environmental Sustainability

From having the stainless steel industry’s lowest carbon footprint to being the supplier of choice for an array of clean tech applications, Aperam is committed to sustainability. To learn more, we talked with Nicolas Changeur, CEO of Aperam Services & Solutions and Chief Marketing Officer for Stainless & Electrical Steel Europe, and Mariane André-Taillé, Aperam’s Group Sustainability Officer.

When it comes to environmental sustainability, how does Aperam differentiate itself from its competitors?

Changeur: Aperam ranks amongst the best in our sector. This is linked to some unique features, which makes Aperam’s CO2 footprint so impressive. In addition, as I will describe later, we are targeting to further improve our environmental footprint.

How is Aperam able to achieve such results?

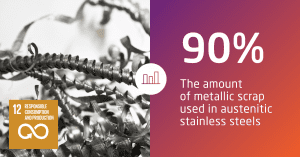

André-Taillé: Our low carbon footprint is the result of three key factors. First, our European electric arc furnaces use scrap metal instead of raw materials. Second, on top of having a very low energy consumption, we also use a low-carbon energy mix. And third, and this is really unique in our sector, Aperam can also be considered an agriculture company, thanks to our more than 100,000 ha FSC®-certified forestry in Brazil (BioEnergia). We use our forests to produce our own charcoal, which we use in our steel-making process as a natural and renewable substitute for fossil fuels (coke). Our forest is continuously cultivated and maintained and is actually carbon positive, which means it acts as a carbon sink.

André-Taillé: Our low carbon footprint is the result of three key factors. First, our European electric arc furnaces use scrap metal instead of raw materials. Second, on top of having a very low energy consumption, we also use a low-carbon energy mix. And third, and this is really unique in our sector, Aperam can also be considered an agriculture company, thanks to our more than 100,000 ha FSC®-certified forestry in Brazil (BioEnergia). We use our forests to produce our own charcoal, which we use in our steel-making process as a natural and renewable substitute for fossil fuels (coke). Our forest is continuously cultivated and maintained and is actually carbon positive, which means it acts as a carbon sink.

What else is Aperam doing?

Changeur: As we do not want to simply maintain the status quo, we announced several objectives to further improve our environmental excellence. In 2019, we announced our sustainability objective of becoming carbon neutral by 2050. Most recently, we announced our aim to further reduce our carbon emissions by 2030 and we are actively working on a detailed roadmap.

André-Taillé: We also use an internal price for CO2. This internal price has been applied to all planned investments since 2016, meaning that our profit calculations include the financial impact of our carbon footprint.

Where does Aperam’s membership in ResponsibleSteel fit into this?

Changeur: Knowing that it’s not enough to only focus on our own sustainability, Aperam is committed to participating in the establishment of sustainable standards for the entire industry. That is why Aperam was the first stainless steel company to join ResponsibleSteel, the industry’s first global, multi-stakeholder certification programme. This membership will allow us to further exchange with our customers and other stakeholders. It also means we are able to play an active role in defining an industry-wide standard and certification mechanism. Once finalised, I am confident that the ResponsibleSteel label will play a prominent role in making the steel industry a true ally in building the sustainable and responsible society we strive to live in.

Changeur: Knowing that it’s not enough to only focus on our own sustainability, Aperam is committed to participating in the establishment of sustainable standards for the entire industry. That is why Aperam was the first stainless steel company to join ResponsibleSteel, the industry’s first global, multi-stakeholder certification programme. This membership will allow us to further exchange with our customers and other stakeholders. It also means we are able to play an active role in defining an industry-wide standard and certification mechanism. Once finalised, I am confident that the ResponsibleSteel label will play a prominent role in making the steel industry a true ally in building the sustainable and responsible society we strive to live in.

Where does Aperam stand on sustainability-orientated regulations?

André-Taillé: Aperam supports new regulations aimed at supporting world-wide sustainability. For example, Europe is considering a carbon border adjustment that, if implemented, would tax potential polluting importers. In parallel, local legislation is already encouraging investments in low-carbon or transition enabling sectors (in line with the EU taxonomy).

The environment – and society – clearly benefit from this commitment to sustainability, but what about the customer?

Changeur: That’s a good question as, at the end of the day, the customer must be convinced of the value of sustainability. In particular, we see a positive movement led by specific sectors like automotive, white goods, and large accounts. But unfortunately, many customers do not yet fully recognise the value of more sustainability. And until their own customers begin requesting sustainable, environmentally friendly products, this is unlikely to change.

This is why education is so important. At Aperam, we also do this by constantly highlighting how our material is sustainably made, how our products use recycled scrap material, and how our production processes rely on renewable energies.

That being said, we are convinced that change is on the way, and that our European customers see sustainability as a way they can differentiate themselves from their non-European competitors. And, as our customers look to lower their carbon footprints, Aperam already offers a range of products ready to serve as the material of choice for the sustainable solutions of tomorrow.

Nicolas Changeur

Nicolas Changeur Mariane André-Taillé

Mariane André-Taillé

2,23%

2,23%