IMPHY® AFK: Cleaner! Faster! Higher!

Home IMPHY AFK: Cleaner! Faster! Higher!

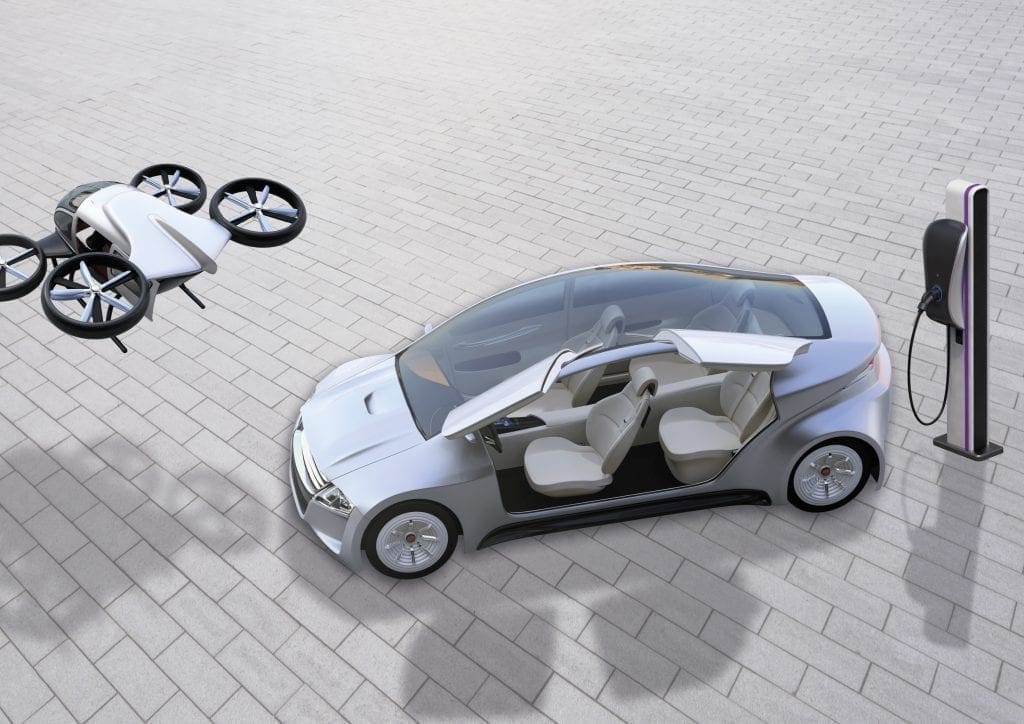

Aperam magnetic alloys: The solution to unlocking the future of e-mobility

The electric revolution of the mobility sector is underway. There’s no turning back, and Aperam is clearly part of it!

The EU Green Deal requires that all new cars registered in Europe be zero-emission by 2035. As a direct consequence, electric motors will become the main propulsion system for many vehicles, not only those on the road, but also those found in the air.

Material performance is a key component in this transition and Aperam’s portfolio of special magnetic materials are true game changers!

With has the competitive advantage of bringing over a century of metallurgical know-how to the table. The impact that the cobalt-based alloys we develop, transform and produce have on the performance of mobility-related e-machines is both well-known and greatly appreciated. Because these alloys are a core compentency, Aperam, together with our partners, is then more than ready to take up the electrification challenge!

The Aperam IMPHY® AFK advantage?

The soft-magnetic material group consists of alloys made with iron, cobalt and nickel. Our iron-cobalt AFK family offers the highest level of saturation, enabling not only the highest power density of electric motors, but also helping to save materials, weight, volume and energy. In fact, we’ve demonstrated that using FeCo can cut an electric motor’s weight by up to 20%.

Furthermore, by reducing losses and improving thermal performance, using these materials unlock battery cost reduction.*

Clearly, our IMPHY® AFK alloys are the sustainable material of choice, opening the door to a new electrified world!

Thanks to their exceptional magnetic properties, FeCo alloys ensure the best performance for both existing and future electrical machines!

*Reference: Aperam official communication at CWIEME Berlin, 11 May 2022, “Impact of Iron Cobalt alloys on performance of e-machines for automotive applications”

How is Aperam innovating in this field?

Aperam covers the two necessary levels of innovation:

1. The ‘material’ innovation: We aim to offer various grades dedicated to specific needs, such as lower magnetic losses or higher mechanical properties, allowing the best trade off between many contradictory properties. This is the mission of the experts at our Research Center, who are working in close cooperation with the Aperam development and industrial teams to meet the expectations of our final customers.

2. The ‘process’ innovation to create the magnetic components (stack or core) that define the electrical machine itself. The impact of the process is a key factor in optimising the final performance. This is the challenge tackled by Aperam’s downstream division, which specialises in magnetic parts manufacturing. Thanks to this division, Aperam is capable of delivering high performance stacks and parts for e-machines.

Our know-how enables optimised material development for the very best in-machine performance. Aperam is partnering with its customers to ensure more than material delivery. Our commitment is to deliver high performance alloys and components demanded by high-performance applications!

-0,71%

-0,71%