Achieving as much as an 85% reduction in carbon emissions

Interview with Jeremy Bouvet, Aperam Business Development and Sustainability Project Manager

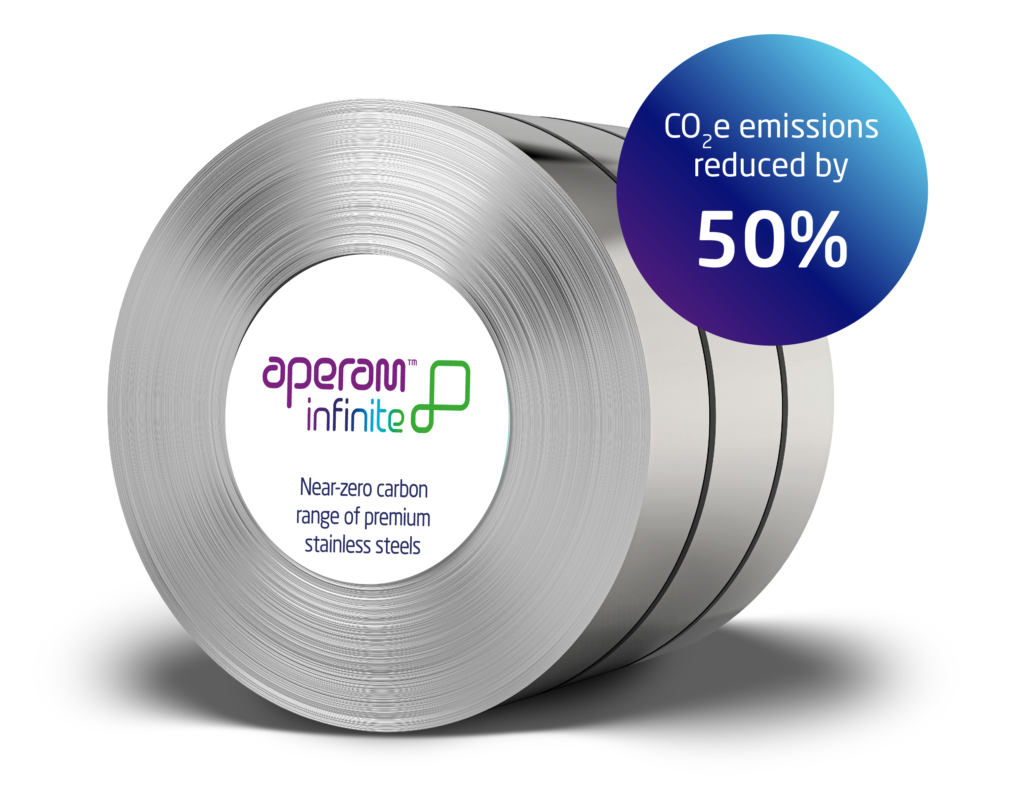

Achieving as much as an 85% reduction in carbon emissions compared to the industry average, Aperam infinite™ stainless steel helps customers reducing their own carbon footprints and join the circular economy. To learn more, we sat down with Jeremy Bouvet.

- Q: To start, could you please tell us what a Sustainability Project Manager does?

Jeremy Bouvet: My role as Sustainability Project Manager essentially involves two core tasks. The first is to keep our customers informed about all the things Aperam is doing regarding sustainability – from recycling to reducing our carbon emissions. Second, I oversee the development and promotion of our range of sustainability-oriented products.

- Q: I assume one of those products is Aperam infinite™?

Jeremy Bouvet: Absolutely. And Aperam infinite™ is a particularly exciting product to talk about. Made with advanced recycling methods, renewable energy, sustainably sourced ores and Aperam infinite is our new product range with low CO2 emissions on the full scope (1+2+3). What makes this product so unique is that it has half the CO2 footprint as our standard products* and is made using up to 100% recycled content.

*scope1+2+3 upstream

- Q: I understand the importance of cutting carbon emissions, but where does the CO2 come from?

Jeremy Bouvet:

When we look at stainless steel’s CO2 footprint, we must account for the product’s entire value chain. We do this by calculating the different scopes as defined in the GHG protocol. Whereas Scope 1 accounts for direct emissions, Scope 2 looks at the carbon footprint of the power being used to produce it.

Scope 3 is divided in upstream and downstream where for Aperam upstream impacts are mainly purchase of materials.

At Aperam, 70% of product carbon footprint is coming from scope 3 upstream, ie the raw materials that we are using, that’s why calculating scope 3 emissions and reducing them are key.

Aperam infinite tackle this scope 3 reduction as it’s made using nearly 100% recycled scrap, we have drastically reduced our need for mined raw materials – which have a very high level of emissions – resulting in a substantially lower carbon footprint for our infinite products

- Q: That is indeed all very exciting. But isn’t it also very expensive?

Jeremy Bouvet:

Yes, low CO2 stainless steel is more expensive for the simple fact that the low CO2 raw materials and quality scrap used to produce it cost more.

But I would like to add that what Aperam is producing and selling – stainless steel – is itself a raw material that our customers use to manufacture products. However, stainless is just one material used in making these products and accounts for a very small part of the product’s final price.

To illustrate, consider stainless steel pots and pans. These products contain maybe one kilogram of stainless, only a few euros worth. So, paying a little more for Aperam infinite stainless steel will have a very small impact on the price of the final product.

Of course, lowering the carbon footprint of a product is about more than just price. It’s about benefiting the planet, and companies have a moral and often a regulatory responsibility to reduce their CO2 emissions.

Aperam infinite helps companies meet their reduction targets. It also gives them an important differentiator as they can market their products as being low carbon – a distinction that is seeing increasing customer demand.

- Q: That makes sense, but how do you ensure that your customers see beyond the higher price tag and understand the advantages that Aperam infinite™ offers?

Jeremy Bouvet: For this, it really depends on how aware a customer is about climate change. Some of our customers have a deep understanding of the issue and are actively seeking ways to reduce their emissions. For these customers, making the switch from standard stainless steel to an ultra-low CO2 option is a no brainer.

Then we have those customers who produce a final product where the stainless steel component is visible to the end user – such as pots, pans and even washing machines. Because the stainless steel can be seen, there is an opportunity for these customers to use reduced CO2 stainless steel as a key market differentiator. A good example here is BSH, the Bosch Siemens Group, who uses Aperam infinite to produce some of its washing machines and dishwashers, which it can then market as being low CO2.

Third are those customers making products where the percentage of stainless steel is very high. Using reduced CO2 stainless is an easy way for these companies to drastically lower their carbon footprints, but we need to educate them on why doing so is important. For instance, MKN, a German company producing professional catering appliances made from 100% stainless steel, is using Aperam infinite to significantly reduce the carbon footprint of its products.

- If a company is on the fence about launching a low carbon footprint product of their own, what would you say to them?

All stainless steel, even that made using a high percentage of recycled scrap, has a big environmental impact – it’s just the nature of an energy-intensive industry like ours. However, there are things we can do to reduce that impact. One of those things is to use materials with low environmental impact when making your products. By using Aperam infinite, one can drastically reduce the footprint not just of that one product, but of your entire company. That’s a pretty big impact for such a relatively small act.

Want to learn more? Contact Jeremy Bouvet

-1,07%

-1,07%