Igniting the Mobility & Transport Revolution

With the automotive, rail, aviation and maritime industries all facing increasing pressure to go green, the mobility and transport sector is quickly shifting gears towards full decarbonisation. Accelerating this shift are such key regulations as the EU’s ban on the sale of new internal combustion engine cars by 2035 and the IMO agreeing to reduce greenhouse gas emissions from international shipping by 100% by or around 2050. Achieving this full-scale decarbonisation demands innovative, disruptive technologies. Top-notch, cost-competitive, and low-carbon materials are essential to these new applications – and Aperam delivers them.

As your material expert, we help you overcome today’s industrial challenges to drive the mobility and transport revolution.

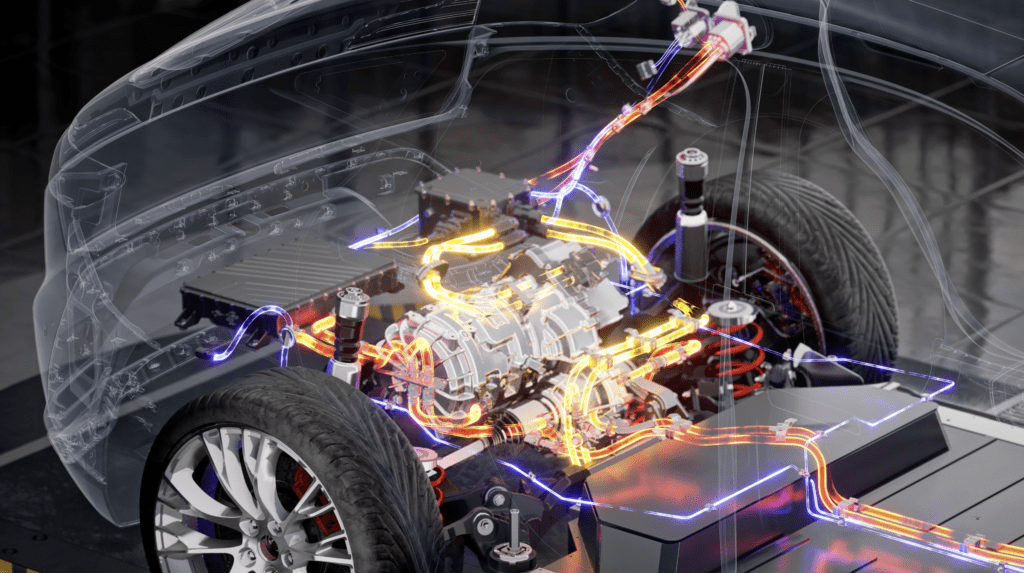

Your Trusted Partner for Navigating the World of Electric Mobility

The entire automotive industry is moving towards an electric future, which poses complex material challenges for critical components. Aperam addresses these challenges by offering a wide array of cutting-edge solutions, including:

- Stainless Battery Housing concept offering the best trade-off between crashworthiness, cost-effectiveness, and weight – while also being fully recyclable.

- Precision Stainless Steels that meet the very demanding performance specifications required for connectors (zero defects, mechanical properties to tight tolerances).

- Nickel-based Alloys that can sustain high temperatures and offer a high electrical conductivity for battery components like busbars, electrode tabs, and current collectors.

- Nanocrystalline Magnetic Cores for power electronics operate at higher frequencies with reduced power loss. They are to be used around the battery or the e-motor of transformers, inverters or on-board chargers.

- Stamped Parts made of specialty alloys for the high-performance e-motors used by premium e-cars and in eVtols, along with for the electric APU in planes. Aperam’s material enables an increased power density for motor rotors and stators – up to 30% – which can lead to a massive reduction in the weight of these electric engines.

Watch the Battery Housing Video below:

Material Excellence to Scale-Up Hydrogen Mobility

The use of hydrogen in the transport sector is expected to grow rapidly over the coming years, especially for light commercial vehicles, heavy duty trucks, off-highway vehicles and even aircraft.

The opportunities presented by this forecasted growth can be broken down into two main areas: fuel cells and fuel tanks.

Fuel cells

The biggest challenge here is developing and producing the high-quality, efficient, and affordable fuel cells needed to power electric vehicles. Bipolar Plates are a strategic component with high added value for fuel cells.

Offering excellent mechanical properties, high formability, low gas permeability, and high electrical and thermal conductivity, our stainless steel for bipolar plates enable improvements in system performance and competitiveness.

Fuel tanks

The use of liquid hydrogen for heavy goods vehicles can significantly increase their range, reduce refuelling times and optimise their payload (charge utile). The challenge is that liquid hydrogen must be transported and stored at cryogenic temperatures.

Offering high strength, excellent ductility, fatigue resistance and weldability, our stainless steel is the material of choice for liquid hydrogen applications.

Liquid hydrogen technology in the field of mobility is undergoing new developments and, thanks to our partnerships with some of the world’s most renowned research institutes, Aperam remains at the forefront of innovation.

Material Solutions Help Decarbonize the Transport of Goods

Responsible for approximately ¼ of global greenhouse gas emissions, the transportation of goods and passengers is facing mounting pressure to decarbonize.

When electrification is not yet an option, low-carbon fuels, synthetic fuels and exhaust cleaning technologies all offer alternative paths towards decarbonization. However, to do so, these innovative solutions require specific material properties.

As a stainless steel and alloys producer, we understand these requirements and, leveraging our deep industrial knoweldge, can help you find the material you need. For instance, within the maritime industry, our resistant stainless steel has emerged as the material of choice for use with such highly corrosive processes as on-board carbon capture (OCC) and NOX selective catalytic reduction (SCR) systems.

-1,71%

-1,71%