Transforming Aperam into a Key Player in Electric Vehicle Battery Housing

Interview with Saghi Saedlou, Head of Mobility & Transport at Aperam

Aperam is disrupting the electric vehicle (EV) battery housing market. Saghi Saedlou emphasizes the critical role that material selection plays in battery housing. Traditionally, this market has been dominated by carbon steel and aluminum. However, stainless steel presents a much better choice, offering superior performance in terms of cost, weight, and safety.

Despite preconceived notions of stainless steel being more expensive, recent developments have proven it to be both technically advantageous and cost-effective for electric vehicles.

- Q: Aperam is a well-known player in the stainless steel industry, but it remains relatively unknown in the EV market. Could you tell us more about Aperam?

Saghi Saedlou: Aperam is a leading global manufacturer of stainless steel and specialty alloys. We operate from two main production sites: one in Europe and another in South America, with a presence in over 40 countries. One key strength of Aperam is our focus on innovation, supported by more than 150 researchers across our three R&D centers. These experts are constantly improving our products and manufacturing processes to meet customer needs in diverse industries, from kitchenware to the automotive sector.

- Q: You have an extensive background in R&D at Aperam, correct? How does your role as Chief Battery Program Officer fit into Aperam’s stainless steel operations?

Saghi Saedlou: Indeed, I spent 15 years in R&D at Aperam after working in various positions in the automotive industry. My experience culminated in the role of Head of R&D, which allowed me to focus on innovation. My current role as Chief Battery Program Officer might seem like a departure from our traditional stainless steel focus, but it’s not. In fact, we are making stainless steel a competitive material for electric vehicle battery housings, traditionally dominated by carbon steel and aluminum.

- Q: Battery housing is typically not associated with stainless steel. Can you explain why Aperam is entering this market?

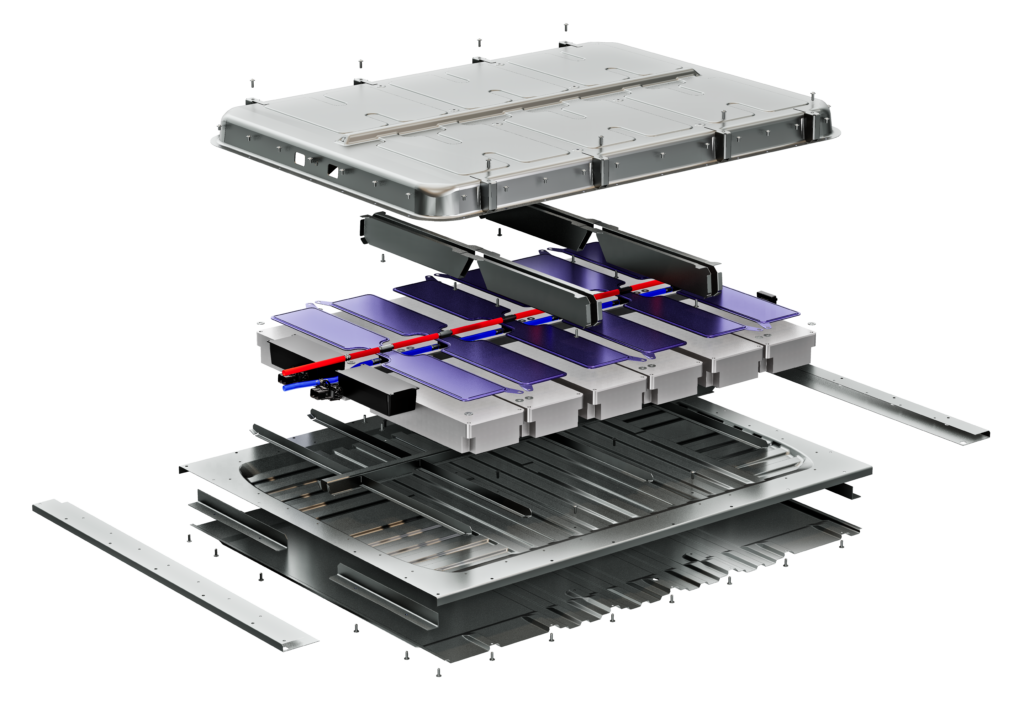

Saghi Saedlou: It’s a natural evolution for us. Battery housing refers to the casing that encloses the battery cells, modules, and electronics in an electric vehicle. Carbon steel and aluminum are the current materials of choice, but stainless steel offers numerous technical advantages. However, the perception is that stainless steel is too expensive. Recent studies have shown that this is not the case. We can meet Original Equipment Manufacturer (OEM) specifications at a significantly lower cost than aluminum, while offering superior technical performance.

This realization led to the creation of a dedicated battery program at Aperam, which includes my role. The EV market is growing rapidly, and Aperam is well-positioned to offer stainless steel solutions tailored to the unique needs of this market.

- Q: What are the biggest challenges you face in your mission to bring stainless steel into the battery housing market?

Saghi Saedlou: The primary challenge is overcoming preconceived ideas about stainless steel, particularly in the automotive industry. Many think it’s too expensive, but we’ve proven otherwise. Our goal is to break down these myths through data and real-world applications.

To achieve this, we are focusing on five key functions of battery housing: crash resistance, weight savings, fire resistance, manufacturability, and sustainability, including life cycle assessments. We designed two different battery housing concepts to showcase how stainless steel can be cost-effective while meeting all the technical demands of modern electric vehicles.

- Q: Can you tell us more about these two battery housing concepts?

Saghi Saedlou: Absolutely. The first concept is designed for maximum weight savings and contributes to the vehicle’s structural resistance. We achieved a weight of 69kg (D-segment vehicle, 88kWh), which is comparable to today’s aluminum solutions, but at a lower cost. The second concept is more forward-looking, focusing on enhancing the vehicle’s volumetric energy density and improving access for maintenance and repair. For this, we leveraged the high formability of stainless steel to create complex shapes.

These concepts demonstrate that stainless steel can meet current and future demands, especially as OEMs push for more efficient, safe, and sustainable materials in EVs.

- Q: You mentioned sustainability earlier. How does stainless steel fit into the broader conversation around sustainability in the automotive industry?

Saghi Saedlou: Stainless steel is highly sustainable, which aligns perfectly with the automotive industry’s push toward greener technologies. Aperam is leading the charge with our use of recycled materials. In our European operations, for instance, we use up to 98% recycled content in our stainless steel production, which helps reduce our carbon footprint significantly. Our stainless steel is fully recyclable, and our electric arc furnaces in Europe are powered by renewable energy, further lowering CO2 emissions.

In fact, Aperam has one of the lowest carbon footprints in the market, with emissions of just 0.32 tonnes of CO2 per tonne of stainless steel produced. This is a key differentiator, as sustainability becomes a central consideration for automotive manufacturers.

- Q: Let’s return to the automotive market. How do you overcome skepticism about stainless steel’s role in EV battery housings?

Saghi Saedlou: It all comes down to data and demonstration. For instance, we’ve shown that our stainless steel solutions offer excellent fire resistance, crash performance, and weight reduction, while also being more cost-effective than alternatives like aluminum. We are not only in the concept phase; we currently have parts on the market that take advantage of stainless steel’s superior thermal insulation and formability.

In addition, full stainless steel systems are already being used in electric trucks, where safety and durability are paramount. So, we are already well past the early development stage and working directly with customers to refine and optimize solutions.

- Q: Given your focus on innovation and market disruption, what’s next for Aperam’s battery program?

Saghi Saedlou: We are constantly looking ahead. Our immediate focus is optimizing our existing solutions and working closely with OEMs to ensure that stainless steel is fully integrated into the next generation of electric vehicles. Additionally, we are exploring new ways to use stainless steel to meet future automotive trends, such as increasing energy density and enhancing EVs recyclability.

At Aperam, we believe that materials play an enabling role in driving technological innovation. Stainless steel, with its durability, sustainability, and technical performance, is the perfect material for EV battery housings and beyond.

- Q: Finally, what role do you see stainless steel playing in the future of mobility?

Saghi Saedlou: Stainless steel has a bright future in mobility. As electric vehicles become more prevalent, the demand for lightweight, strong, and sustainable materials will only grow. Aperam is positioned to be at the forefront of this evolution, offering stainless steel solutions that meet the highest standards of safety, performance, and sustainability.

Our materials are not only part of the battery housing solution but can contribute to other critical components, including structural parts and thermal management systems. We are committed to pushing the boundaries of what stainless steel can do in the automotive sector, ensuring that it remains a key material in the future of mobility.

For more information about Aperam’s innovations in the stainless steel industry, or to learn more about our battery housing solutions, feel free to reach out to our team.

Head of Mobility & Transport

3,81%

3,81%