Nanocrystalline magnetic cores have the potential to power the mobility revolution

To learn more, we sat down with Charles David, Head of Consumer Goods & Construction at Aperam.

With a PhD in metallurgy, saying that Charles David is passionate about alloys and stainless steel – and the innovation they offer – would be an understatement. As part of the Aperam’s Market Innovation & Development team, he’s transforming that passion into value-added solutions for our customers.

One of those solutions is nanocrystalline magnetic cores, which Charles says have the potential to power the mobility revolution.

- Q: What are magnetic cores and why are they so important to the e-mobility sector?

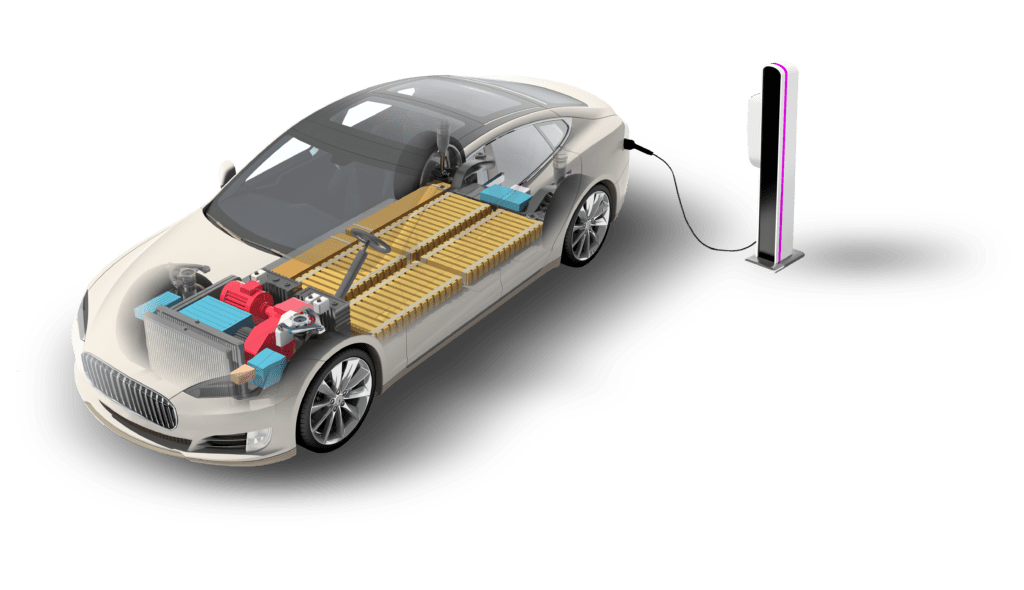

Charles David: Electric vehicles, or EVs, are composed of several different electrical systems. Although all these systems require power to work, the type of power they need differs from system to system. While the vehicle’s battery stores the power, the power electronics transform it into the type of power that can be used by the other systems.

To illustrate, take the inverter – which is a converter that transforms the DC current coming from the battery into the AC current that powers the motor. When this transformation happens, it creates electromagnetic interference that could have a negative impact on the vehicle’s other systems. Magnetic cores are used to filter this interference and protect the other systems.

- Q: Where does the nanocrystalline come in?

Charles David: Our magnetic cores consist of a coiled metallic ribbon made from a nano crystalline alloy. This nanocrystalline alloy – which is composed primarily of iron, silicon, niobium and boron – has very small grains in its metallurgical microstructure that give it special magnetic properties.

- Q: Why is Aperam investing energy and resources into developing nanocrystalline magnetic cores?

Charles David: First and foremost, thanks to the rapid growth of the EV market, demand for magnetic cores is booming right now – and Aperam is uniquely positioned to leverage this market opportunity. We’ve been able to take our years of experience in working with magnetic cores for the demanding electrical safety and aerospace industries and apply it to the EV market.

But we’re not just talking about magnetic cores. We’re talking about nanocrystalline magnetic cores – a high added value core that offers our customers a number of advantages over traditional ferrite cores.

- Q: What are some of those advantages?

Charles David: Compared to ferrite cores, nanocrystalline magnetic cores offer better temperature stability and higher permeability. They are also smaller than ferrite cores, which opens the door to more possibilities in terms of designing parts and has a positive impact on total cost of ownership.

- Q: How big of a market opportunity is this?

Charles David: Today, nanocrystalline magnetic cores are found in less than one out of every three EV inverters. However, our estimates indicate that by 2030, they will account for over half of all magnetic cores on the market.

- Q: Any key takeaways you want our readers to remember?

Charles David: The development of new materials and materials expertise are two important keys to making the e-mobility revolution more affordable. Every step we take in improving the performance of a vehicle’s components is a step towards making the EV more competitive – and that’s exactly what Aperam is doing with our nanocrystalline magnetic cores.

Want to learn more? Contact Charles David

Head of Consumer Goods & Construction

2,40%

2,40%